MECHANICAL AND ELECTRICAL ENGINEERING

Sustainable Applications

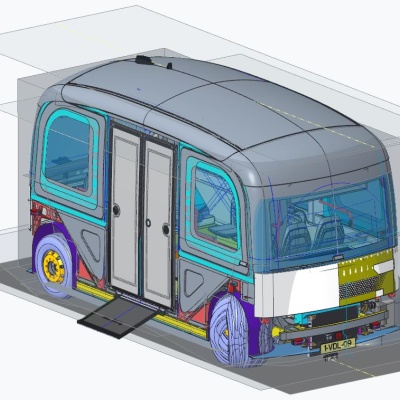

As VDL ETS, we fully support innovative and sustainable solutions for both static and dynamic applications. Our rich experience in the field of vehicle, vessel and mechanical engineering enables us to effectively combine today's energy transition with our automotive expertise. This has led to our focus on off-grid solutions - perfect for understanding, serving and improving the overall ecosystem.

Quality through Experience and Innovation

Our formula for success is the result of a unique balance between our rich history and a constant curiosity for innovations. We believe that ‘Heritage of Tomorrow’ equals ‘Innovation of Today’. A great example of this is our use of modular building blocks, which allow us to implement innovative technology without major design uncertainty.

Product Lifecycle Management

VDL ETS uses a Windchill Product Lifecycle Management (PLM) server as the leading tool for all engineering processes. This allows us to store our data in a centralized and secure environment which adheres to all ABDO requirements for defence projects. Together with our internal system administrators, the system can be flexibly configured to suit all projects. This ensures an efficient way of working with the latest released data for all departments in the company and our clients.

Discover the power of innovation and collaboration with our team and be part of the future of sustainable technology!

Working with market leaders

A Complete Design Process

Flexibility in Production