Pressure and burst testing

Pressure Testing – Proof, Burst & Pulsation

Our pressure testing facilities provide a complete picture of component performance under extreme conditions. From proof and burst tests to lifetime pulsation cycles, we ensure your parts meet the highest safety and durability standards.

Capabilities

Burst Testing: from 0.1 up 7,500 bar customer made setup for ultimate strength validation

Oil-Based Rigs: from 0.1 up to 1,500 bar for burst testing, pulsation testing, and lifetime testing

Water-Based Rigs: from 0.1 up to 250 bar for burst testing, pulsation testing, and lifetime testing

Custom High-Pressure Pneumatic Solutions: lifetime and durability rigs

All when required with temperature & humidity control up to 300°C for combined thermal and pressure cycling

Test Methods

- Pressure Proof Tests – Hold pressure for a defined time and check for leakage

- Burst Tests – Increase pressure until failure to determine ultimate strength

- Pulsation Tests – Simulate real-life pressure cycles for lifetime validation

- Leak Detection – Integrated checks during pressure and pulsation tests

Applications

Hydrogen (H₂) Systems: fuel tanks, valves, and connectors for zero-emission mobility

Automotive & Mobility: drivetrain and load-carrying components, engine parts under thermal and mechanical stress

Material & Component Testing: rubber seals and elastomer components, tin-based and lightweight metal parts

High-Tech Industry: vacuum chambers and outgassing-sensitive systems, semiconductor and precision assemblies

Aerospace & Aviation: hydraulic systems, actuators and fuel lines under extreme pressure.

Structural components for aircraft and satellites

Energy & Power Systems: high-pressure pipelines for oil, gas, and hydrogen

Components for renewable energy systems (e.g., hydrogen storage, offshore wind)

Medical & Pharmaceutical: high-pressure vessels for sterilization and fluid systems. Leak integrity for medical devices and packaging

Industrial Equipment: compressors, pumps, and valves for heavy-duty applications. Pressure chambers for process control and safety validation

Defense & Security: armored systems and pressure vessels for military applications. Leak-proofing for critical safety systems

Electronics & High-Tech: pressure-resistant housings for sensors and robotics

Example of reference Methods

ASME Boiler & Pressure Vessel Code

- Section VIII, Div. 1 (Pressure Vessels)

- UG-101 (Proof Test Method)

ASME Piping Codes

- B31.1 (Power Piping)

- B31.3 (Process Piping)

ISO & EN Standards

- ISO 4548-5 / ISO 4548-6 – Pulsation and burst tests for hydraulic filters

- ISO 1167 / ASTM D1598 – Hydrostatic pressure testing for plastic pipes

- ISO 9080 / ASTM D2837 – Long-term hydrostatic strength

BFPA/P100 – Guidelines for proof and burst pressure testing of fluid power components

ASTM D1599 – Resistance to short-time hydraulic pressure of plastic pipes

API Standards – For pressure vessels and piping in oil & gas

Pressure Pulse Testing: Durability Under Dynamic Load

At VDL ETS, we offer advanced pressure pulse testing to validate the fatigue resistance and sealing integrity of components under fluctuating pressure conditions. These tests simulate real-world operating environments where parts are exposed to repeated pressure cycles, temperature variations, and different media.

Test Capabilities

- Hydraulic Pulsations: Up to 10 Hz frequency and 50 bar pressure. Ideal for testing hydraulic systems, couplings, and tubing under dynamic load.

- Air Pulsations: Up to 2 Hz frequency and 7 bar pressure. Suitable for pneumatic systems and air-driven components.

- Coolant Pulsations: Possibility to test with coolant using a medium separator, enabling realistic simulation of thermal and chemical stress.

- Temperature Range: Testing at temperatures up to 300°C, for components used in engine compartments, industrial systems, and thermally demanding environments.

Applications

Pressure pulse testing is essential for:

- Seal and joint validation

- Fatigue analysis of fluid systems

- Development of cooling modules and heat exchangers

- Quality assurance of automotive and industrial components

- Reliable Test Data for Robust Designs

Our test setups are built for long-term cyclic loading and precise monitoring of pressure, temperature, and media behavior. Results can be correlated with FEM simulations or used directly for design optimization.

Burst Testing

Verifying Maximum Pressure Resistance

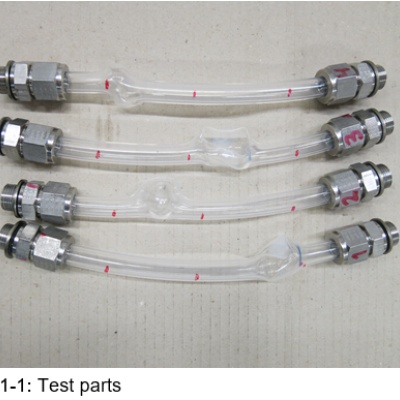

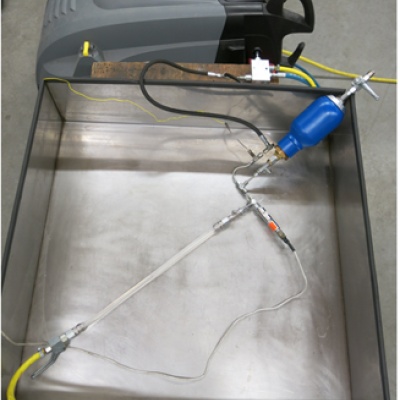

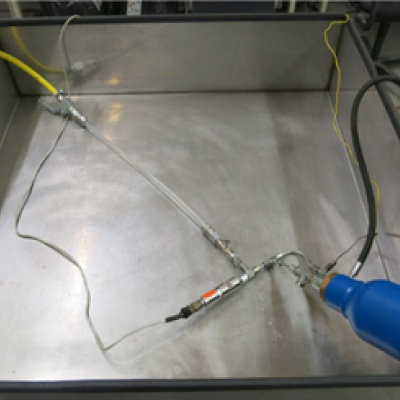

At VDL ETS, we perform burst tests on THV hoses and connectors to assess the robustness and safety of these components. This type of testing is crucial for applications where hoses are exposed to high internal pressures, such as in automotive, industrial, or chemical systems.

What is a Burst Test?

A burst test is a destructive pressure test in which a hose or connector is subjected to increasing internal pressure until it fails. The pressure is gradually raised under controlled conditions, and the failure point is carefully monitored. This provides valuable insights into:

- The maximum pressure resistance of the system

- The failure behavior of materials and joints

- The safety margins relative to the operating pressure

Testing Capabilities at VDL ETS

- Applicable to THV hoses and associated connectors

- Controlled pressure buildup with precise monitoring and data logging

- Visual and digital capture of the failure event

- Analysis of failure location and material response

- Comparison with specifications or FEM simulations

Why Perform Burst Testing?

- To validate design and material selection

- For quality control of production batches

- To assess risk in critical applications

- To support certification and customer requirements